Beer love post: how real Guinness was brewed

Categories: Europe | Food and Drinks | History

By Pictolic https://pictolic.com/article/beer-love-post-how-real-guinness-was-brewed.htmlIn 1759 Irish brewer Arthur Guinness signed a lease on an abandoned brewery at St. James's Gate in Dublin. The annual rent was £45 and the lease term was 9,000 years.

At first, only ale was brewed, the business brought a good income. The first batch of Irish beer was exported to England 10 years after the signing of the contract. In 1799, noticing that Dublin porters preferred a pint of dark beer to ale, Guinness decided to reorient production. The variety got its name thanks to the people for whom it was brewed - porter (from the English word "porter" - loader). A few years later, Arthur Guinness porter became a world-famous stout.

(Total 22 photos)

At the turn of the XIX-XX centuries, the company began to hire scientists who developed new brewing technologies. The chemist Alexander Forbes-Watson founded a whole research laboratory in St. James's Gate, which was soon followed by an experimental brewery.

In August 1953, a Picture Post photographer was able to get into the holy of holies of all beer drinkers. By that time, the Guinness brewery was considered the largest in the world, producing 80% of the total hoppy drink in the country. These photographs depict a sacred process in which water, malt, barley, hops and yeast are crushed, mixed, brewed, fermented and filled with barrels branded with the iconic Irish drink.

Henry Barter relishes lighting his pipe right after downing a pint of Guinness at John Mullet's Pub in Dublin.

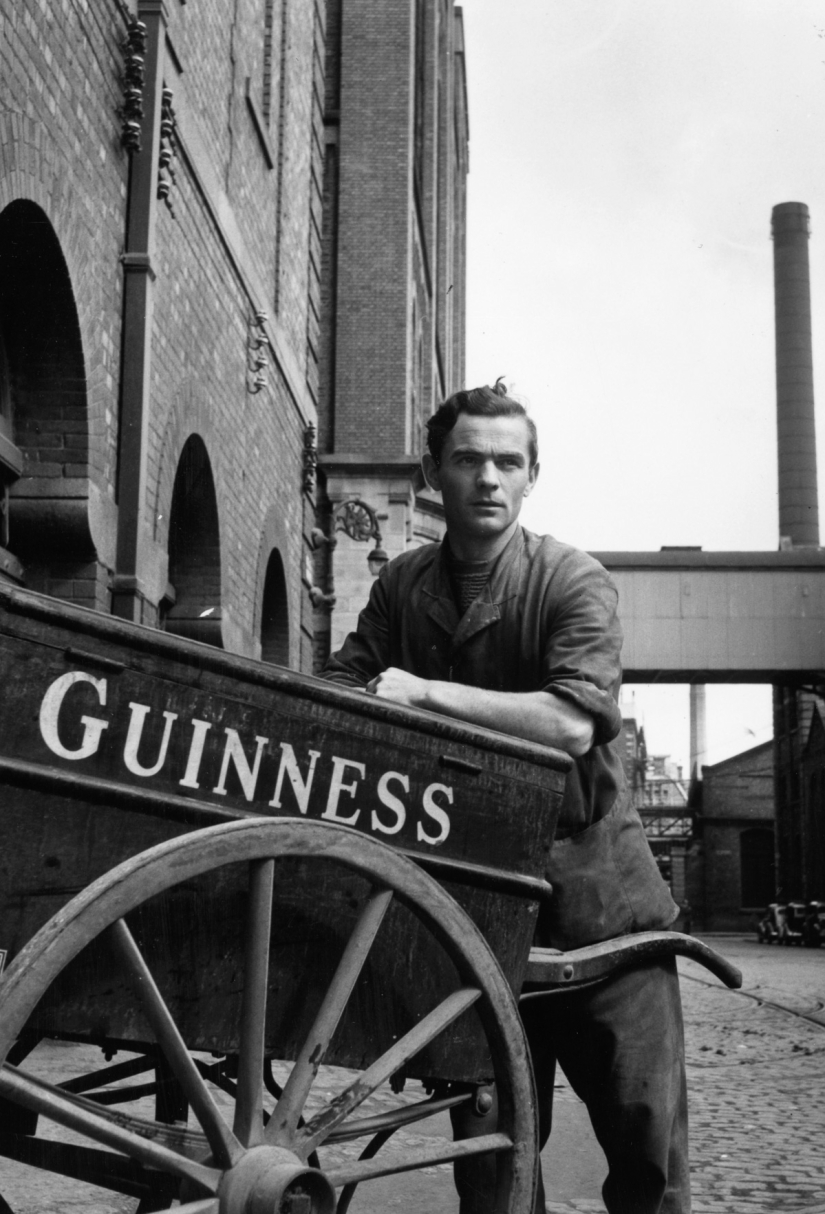

Eugene Hackett leaned on a cart that was being used to transport malt around the brewery.

Workers at the brewery.

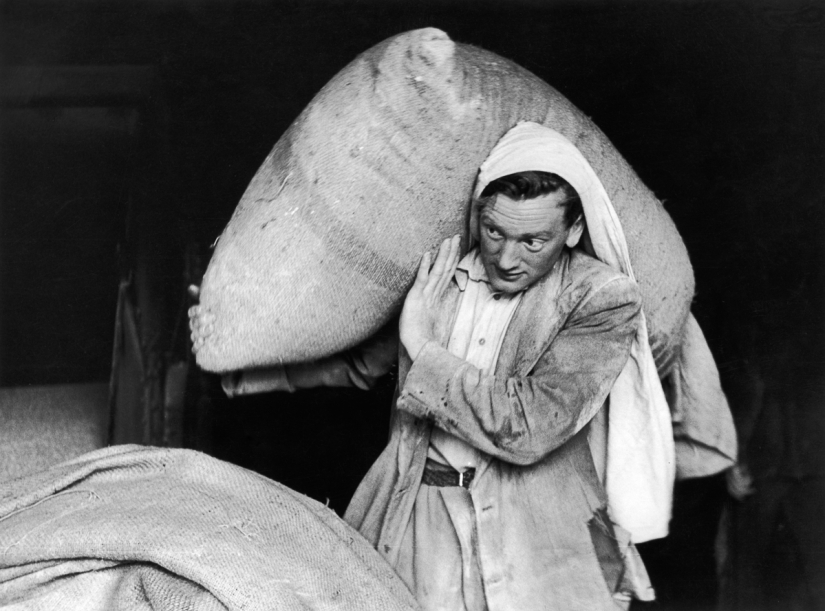

A worker drags a sack of malt into a warehouse.

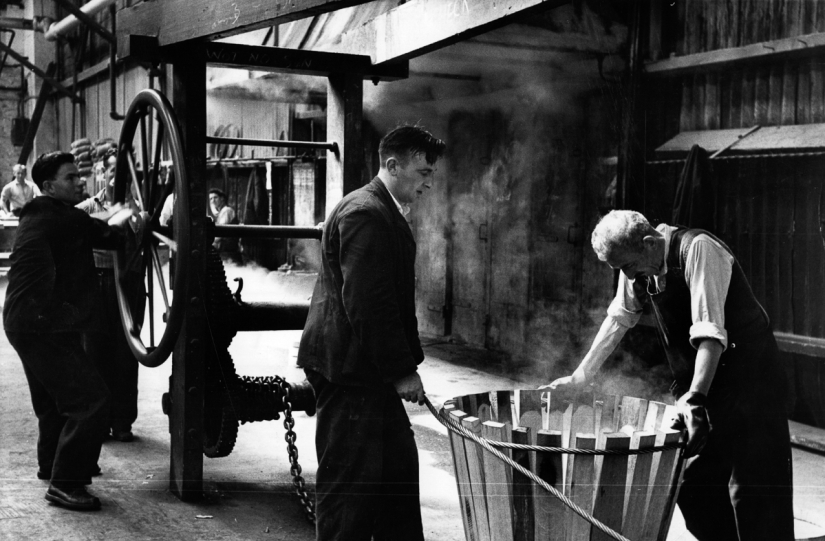

Assembling a new barrel. Later, it will be filled to the brim with intoxicating Guinness.

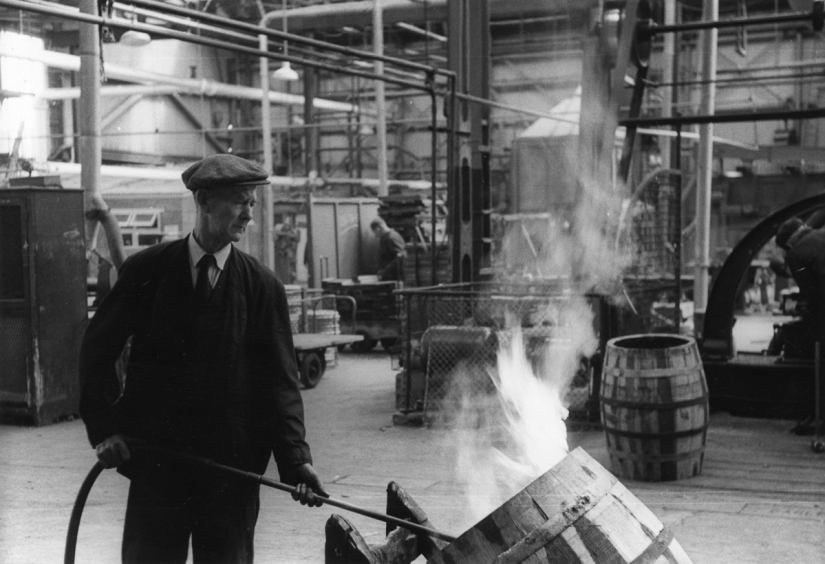

Joe McCarthy fires an assembled barrel.

The worker sews special covers that served as protection for beer barrels during transportation.

A worker clears the chute to prevent hop residue from entering the wort kettle.

Workers pour beer from the boiler.

Wort vat cleaning.

A brief respite before the man continues cleaning the wort vat again.

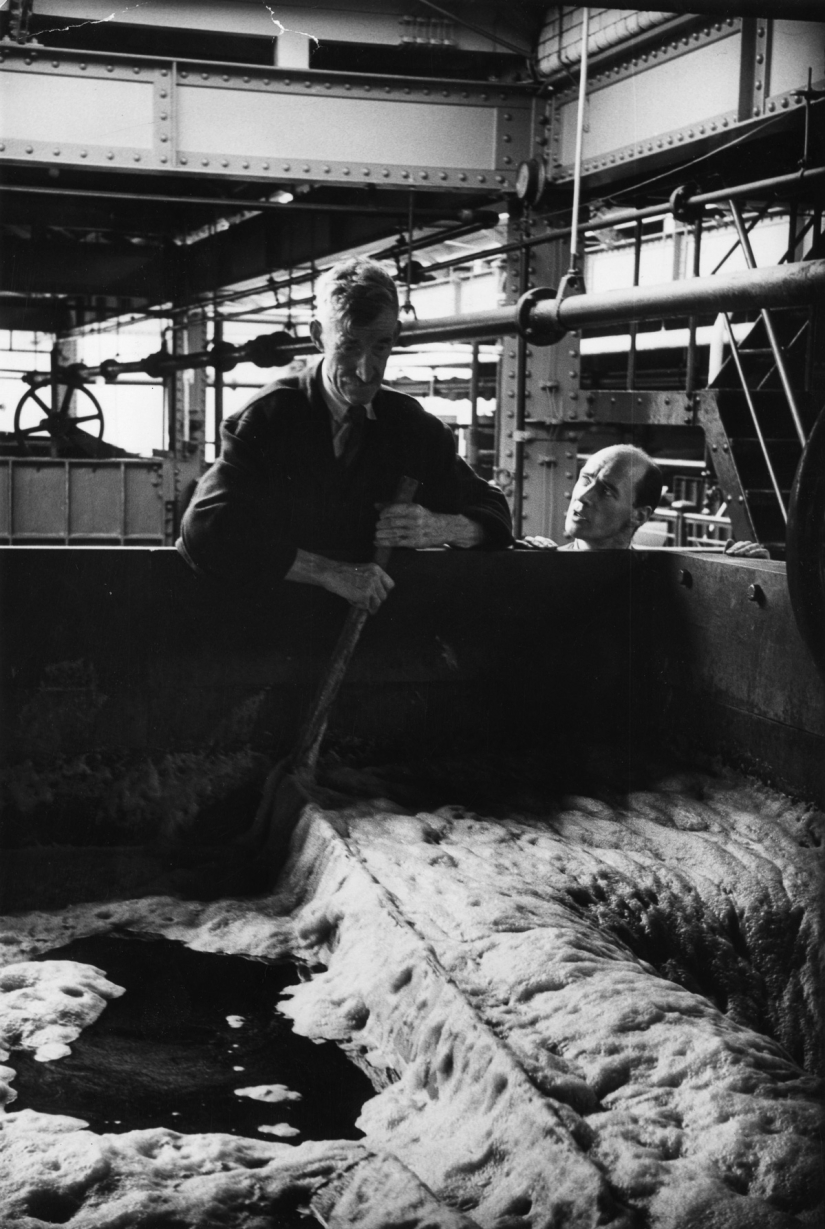

In this huge "pool" the yeast foam was removed from the beer before the drink was sent to another vat.

A worker oversees the removal of foam from beer.

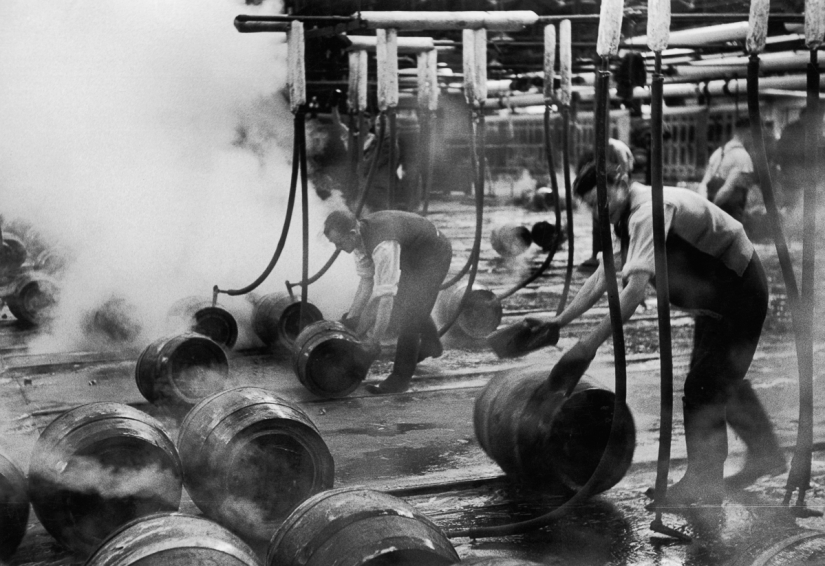

In a special workshop, the barrels were scalded from rubber hoses.

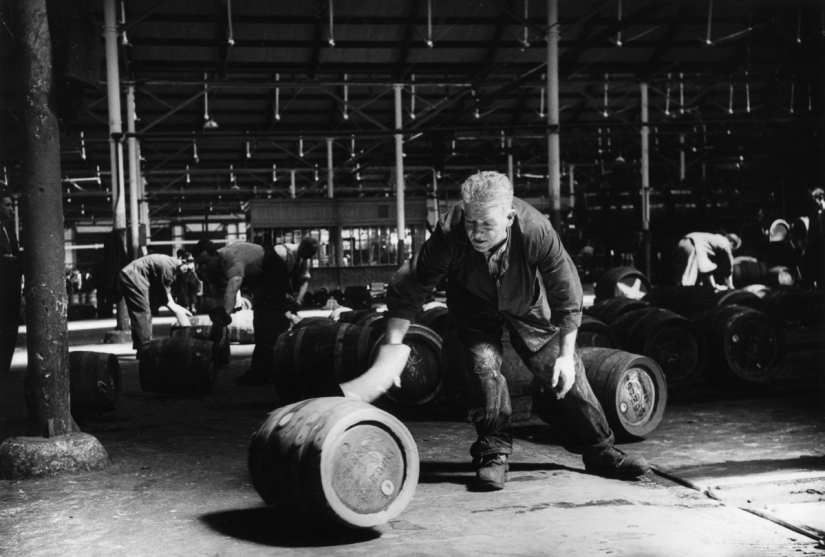

The scalded barrels are rolled to the next workshop.

Paddy Farrell rolls out finished kegs.

James Mayer brands the container with a company logo.

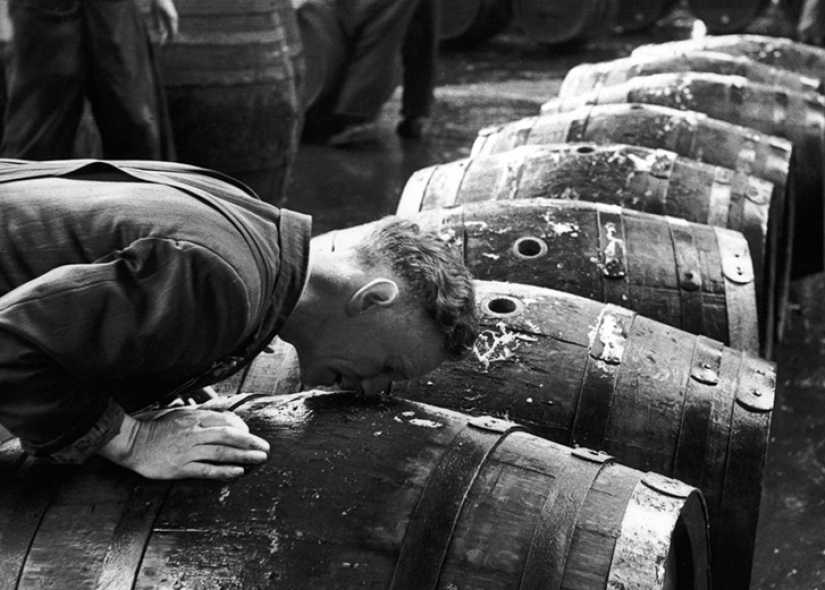

A special "sniffer" checks the quality and cleanliness of the barrels.

Here, ready-made capsules were filled with beer.

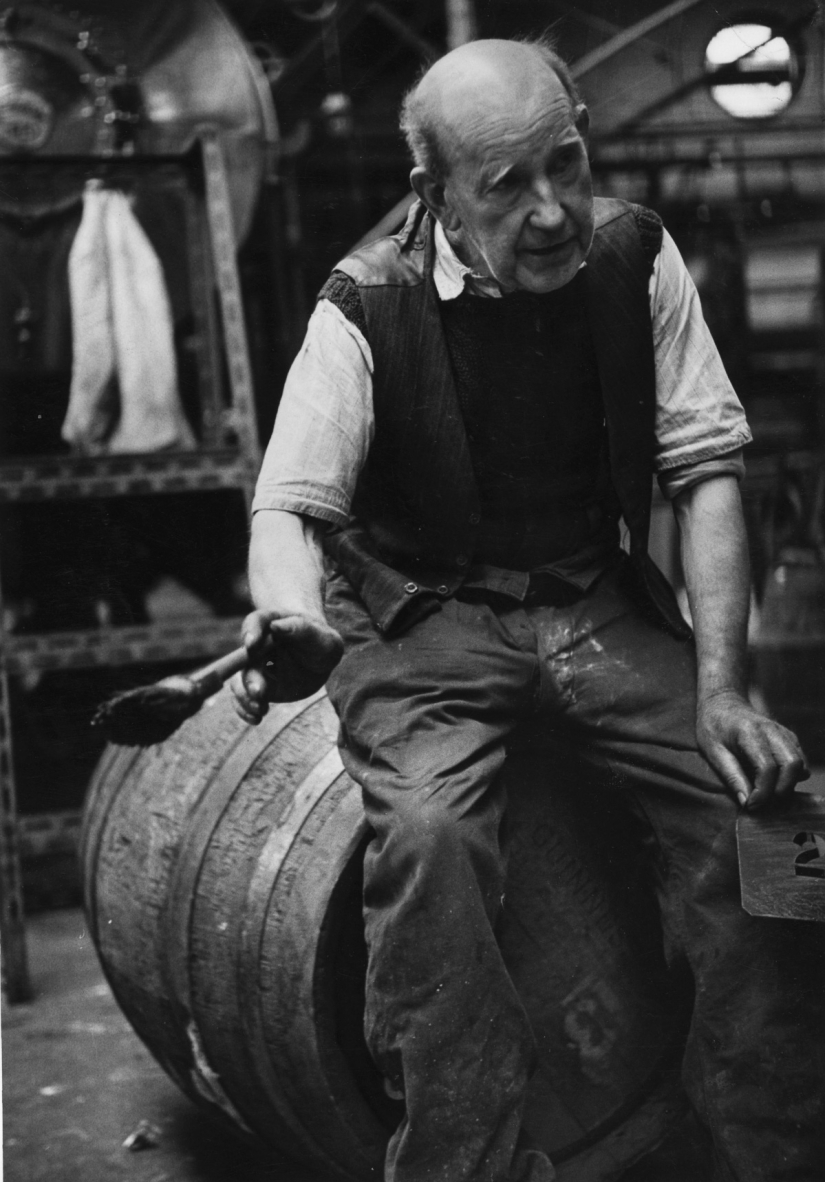

The worker rests with his foot on a barrel full of ale.

Henry Barter enjoys another pint of the legendary Guinness stout.

Keywords: Beer | Brewing | Process | B/w

Post News ArticleRecent articles

It's high time to admit that this whole hipster idea has gone too far. The concept has become so popular that even restaurants have ...

There is a perception that people only use 10% of their brain potential. But the heroes of our review, apparently, found a way to ...

Related articles

It is believed that the appearance of gray hair — it is a sign of aging, the gradual extinction of the organism. Many ...

Choosing a gift for a birthday or any other significant date can be excruciatingly difficult. But there are always classic options ...

We offer you an animated story about how to make... strawberry beer. Yes, yes, strawberry. No chemicals, only natural products! ...

New Year's is a time to surprise and delight loved ones not only with gifts but also with a unique presentation of the holiday ...