Jeans are killing our planet, but we only found out about it now

Categories: Ecology | Nature | Production | World

By Pictolic https://pictolic.com/article/jeans-are-killing-our-planet-but-we-only-found-out-about-it-now.htmlEvery day more and more is becoming known about the threats that humanity brings to nature. We are concerned about the emissions of enterprises, ozone-depleting aerosols, deadly plastic for animals, toxic batteries and much more. Now you can safely add jeans to this list, which, as it turned out, make a significant contribution to the destruction of the environment.

The most expensive, most powerful and most toxic car in the world is the Bugatti Chiron. The 8-liter engine of this monster, which has a power of 1500 hp, produces 516 grams of CO2 for every kilometer traveled. Buying jeans, you cause such damage to the environment, as if you are driving this supercar 26 km.

13 kg of carbon dioxide gets into the air when making just one classic jeans. A large tree needs to spend 4.5 months to get rid of this amount of CO2. Now imagine that every year humanity produces 4 billion pairs of jeans, which is accompanied by the release of 52 million tons of CO2.

But that's not all. It is known that for the production of only one unit of such products, the manufacturer consumes up to 10 kg of chemical dyes and 8 thousand liters of water. In this regard, many responsible buyers of clothing have already abandoned denim clothing and prefer things made of environmentally friendly materials.

The biggest problem of jeans is the cotton from which their fabric is created. This agricultural crop consumes huge amounts of water, and also occupies an impressive area. According to Cotton Outlook, 150 million hectares are occupied by cotton on the planet.

In addition, the culture grows in a hot, arid climate, where there are already constant problems with water. To grow 1 kg of cotton, 22.5 thousand liters of water are consumed in India. The Aral Sea in Central Asia is a typical example of what cotton cultivation can lead to if mindless irrigation is carried out at the same time.

But studies show that water standards for cotton cultivation are excessive. It is quite possible to manage 10 thousand liters, and sometimes 8, as they do in the USA. The rejection of pesticides makes the used water suitable for further use.

To achieve all this, there is no need for high—tech technologies - it is enough to use irrigation channels with concrete, not sand or soil bottom, efficient pumps and special systems with hoses that supply water directly to plants.

The use of drip irrigation reduces water consumption even more, but requires significant investments in equipment. The pipeline system created in the cotton field will allow water to be supplied directly to the bushes, making losses minimal.

In order to help farmers grow cotton with minimal harm to the environment, the international non-profit organization Better Cotton Initiative (BCI) was established in 2005. It was supported by such giants of light industry as Adidas, Gap, H&M, Ikea.

The main objective of BCI is to help farmers interested in growing organic cotton. The organization helps to look for investors, as well as manufacturers interested in obtaining environmentally safe raw materials.

The activities of the Better Cotton Initiative have already begun to bring tangible results. Thanks to the work of the organization, it was possible to reduce water consumption by cotton plantations in Tajikistan (3%) and Pakistan (20%). China and Turkey are also actively fighting to reduce environmental damage.

In addition to saving water resources, there is another positive point — all cotton companies cooperating with BCI completely abandon pesticides and other chemical compounds that harm nature.

The second global problem associated with the production of jeans is dyes. Strange as it may sound, but for 150 years the technology of dyeing fabrics has not changed and still requires huge amounts of water and a large amount of toxic reagents and dyes.

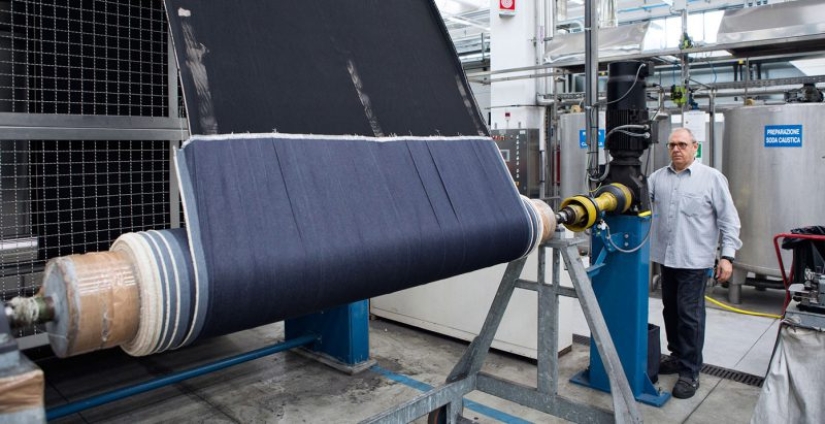

When preparing the fabric for painting, it is bleached using caustic compounds and treated with a special compound that reduces the friction of the threads when moving along the conveyor. The breakage of even one thread in this case becomes a real disaster — a roll in which about 700 meters of fabric turns out to be unusable.

After that, the coloring takes place in 12 baths with indigo, and after each stage of coloring, the fabric is thoroughly dried. To fix the paint, a hydrosulfate solution is used — it reduces the size of the paint particles and ensures their better penetration into the fibers.

The technological line of denim coloring has a length of 52 meters and paints 19 linear meters of material per minute. At the same time, 95 thousand liters of water are consumed! Companies such as Levi's, Wrangler and Lee use water of a repeated cycle, cleaning it with special installations. But not all manufacturers can afford such equipment.

Firms that produce jeans of the cheapest segment, as well as numerous workshops for the production of counterfeit goods, simply drain blue water from indigo into the nearest river without caring at all about the consequences. It is also impossible to say that water from factories of well—known brands becomes completely safe - it remains technical, unsuitable for drinking and watering plants.

In the world, about 783 million people suffer from a shortage of drinking water, so it is impossible to call the rational approach of companies that produce jeans. In this regard, an original way out of the situation was found, which was called "dry coloring".

The creator of the new, safe coloring technology was the Spanish company Tejidos Royo from Alicante, Valencia. The family business, started back in 1903, at the beginning of the XXI century began to suffer from increased costs. To get out of the situation, Tejidos Royo, in cooperation with the manufacturer of denim dyeing equipment Gaston Industries, has developed a unique coloring line, the length of which is only 8 meters, with a water consumption of 36 liters per minute. At the same time, the technique allows you to paint not 19, but as many as 27 meters of denim during this time.

"Dry coloring" differs from the usual one in that it is produced in a nitrogen-saturated atmosphere, pre-foamed with indigo dye. The foamed dye penetrates the fibers perfectly, and the absence of oxygen in the painting chamber provides coloring in one cycle.

The technology excludes the use of other chemical reagents, including dangerous hydrosulfate. This not only helps to protect the environment, but also saves manufacturers huge sums. The discovery of the Spaniards turned out to be so successful that it was adopted by the Wrangler company, which is actively involved in environmental programs.

The third problem of the denim industry can be called waste. In the USA alone, at least 13 million tons of clothing are sent to landfills annually, among which a considerable part are denim items. This does not include the "contribution" of the textile and clothing industry, which also produces a lot of scraps.

Studies have shown that up to 95% of cotton items and waste can be reused, reducing the negative impact of denim production on the environment. Today, recycled clothing is not used too rationally, turning into cheap products such as rags and various soft fillers.

But gradually there are ways to use this raw material more effectively. A cotton T—shirt can be recycled and turned into a hoodie, and this wardrobe item, after the end of its service life, into a bedspread. Why is that? The fact is that each processing makes the threads shorter and coarser, and therefore they have to be used to produce denser products. So far, only two processing cycles are possible, but work is underway to improve the technology.

Washing is the fourth factor of influence on the environment. To make jeans look fashionable and stylish, they are "aged" after manufacture. This technology was developed by Jack Spencer for the Lee brand, but it is now used by almost all companies.

To lighten jeans, they are washed in special water-based formulations, to which chlorine, cellulose enzymes and several other chemical compounds are added. Pumice stone is also added to the water, creating a scuffing effect. Of course, this process consumes huge volumes of water, which is almost impossible to clean qualitatively.

Also, do not forget that such washing harms the health of factory workers who suffer from serious occupational diseases. In some underdeveloped countries, such washing in reagents is done without protective equipment, and sometimes just with bare hands.

In 2017, several companies found an effective innovative way to wash denim without chemical compounds. Instead of chlorine and pumice, they started using a laser, which is not only safe for nature and employees, but also significantly improves the quality of processing. A half-hour labor-intensive washing has now begun to take only 90 seconds, while accidental damage to the fabric fibers and uneven changes in the color and texture of the material are excluded.

To lighten the fabric, ozone is used by feeding it into washing drums instead of caustic chemical compounds. It perfectly dissolves indigo and leaves the water relatively clean. The use of ozone for washing is not new. In dry cleaners, it has long been used to remove particularly persistent contaminants. Of course, in the case of bleaching denim, the concentration of ozone is much higher.

Such washing allows you to save 50-60% of water, so it was adopted by Levi's, Lee, Wrangler, Uniqlo, Guess, struggling for the rational use of water resources. Recently, more modest manufacturers from India, Turkey and Pakistan have begun to follow the example of fashion giants.

How can we help the conservation of nature from the denim disaster? Do we really have to give up our beloved jeans, denim jackets and shorts? Of course not! To make a modest but important contribution to the protection of our planet, it is enough to abandon the products of unknown manufacturers of the lowest price segment.

Almost all companies producing medium-budget and high-end products have long since switched to production with minimal environmental impact. Technologies that help protect nature are still expensive, although scientists are struggling to make them cheaper. By purchasing high-quality products of well-known brands, we not only reduce the impact on the environment, but also contribute to the financing of new, advanced technologies. Therefore, we can say that being fashionable today also means being conscious, and this is very important.

Recent articles

It's high time to admit that this whole hipster idea has gone too far. The concept has become so popular that even restaurants have ...

There is a perception that people only use 10% of their brain potential. But the heroes of our review, apparently, found a way to ...

New Year's is a time to surprise and delight loved ones not only with gifts but also with a unique presentation of the holiday ...