How the best Cuban cigars are made

Categories: Production

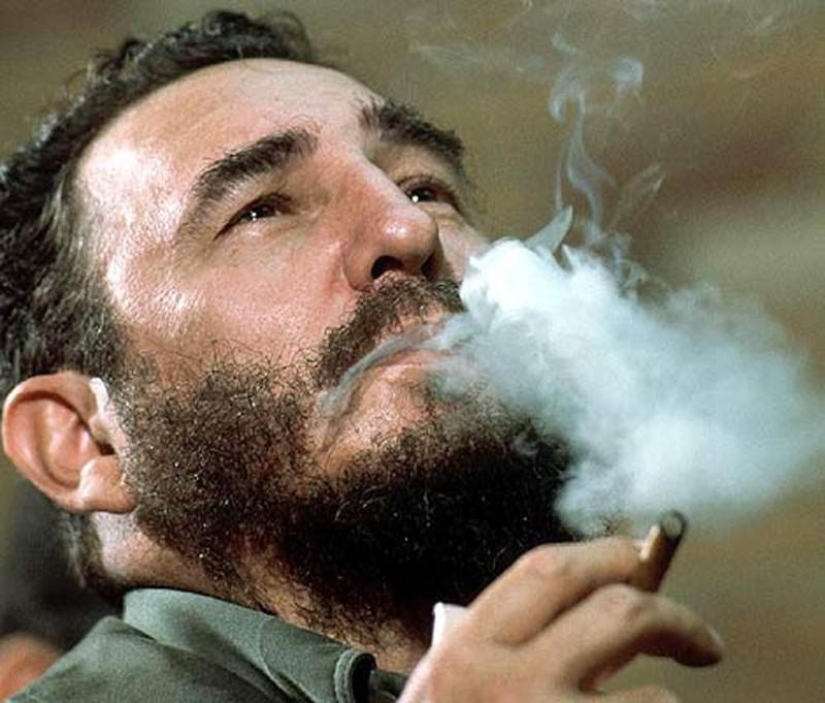

By Pictolic https://pictolic.com/article/how-the-best-cuban-cigars-are-made.htmlUntil the early 1980s, Cohiba cigars could not be bought for any amount of money. Only high-ranking guests of Cuba could receive them as a gift. The villa where they are made belongs to Fidel Castro himself, the entrance is by special permission. What is going on inside?

(Total 18 photos)

1. Cohiba is one of the youngest brands of Cuban cigars, but in a fairly short period of time its products managed to acquire a cult status and become desirable in the collection of every self-respecting smoker. The history of the brand has been traced back to 1969.

2. For Cuba, it was a transitional period: relatively recently, the revolution died down, loud political slogans were slowly but surely put into practice by Fidel Castro and his faithful henchmen. Under these conditions, the production of elite cigars is opened at the El Laguito villa owned by Fidel. It was headed by Eduardro Riviera, who had previously worked at another factory - La Corona.

3. It is not known what reached Castro faster - rumors about the outstanding skill of the tobacconist or the aroma of his surprisingly strong cigars, but the fact that Riviera was present at the new factory clearly speaks in his favor.

4. The success of the Cohiba brand is largely predetermined by the use of the highest quality tobacco from the plantations of Pinar del Rio, which, unlike the factory itself, are regularly organized tours. By the way, if you still really want to personally visit the production of cigars, the Tabacalera De Garcia factory in the Dominican Republic is open for tourist excursions. Note that the tobacco used in the production process of real Cuban cigars does not contain any foreign chemical impurities and pesticides. For the Cohiba brand, the rarest and thinnest leaves are used.

5. Mandatory first step in the production of cigars - fermentation. The fermentation process is particularly complex and itself takes place in several stages. Its ultimate goal is to improve the taste of tobacco and reduce the content of nicotine, various tars and ammonium in it. First, the collected leaves are dried in strictly sealed bags. Repeated fermentation introduces specific flavors into the dried leaves, while the tobacco is stored in a dark closed room. The final, third, fermentation stage is designed to clean the leaves used for filling cigars as much as possible. Compliance with all stages of this complex biochemical process provides each real Cuban cigar with a persistent unforgettable aroma and excellent quality, worthy of the ambitions of the declared premium brand.

6. After the tobacco is brought to light after a long fermentation process, it goes on an equally long journey through the shops of tobacco factories. They control the movement of tobacco between tobacco shops, each of which performs its own range of work. Such workers are called tabaquero, and among them, by the way, there are quite a few women.

7. Tobacco is cleaned of deformed leaves and insects, sorted by color, thickness and quality, get rid of large leaves, after which it is sent to the next production line - blending. At this stage, prepared tobacco leaves are selected according to their varietal characteristics, and then they are mixed. The main thing seems to be to determine the aroma of essential oils and make a varietal mixture based on them. This is perhaps the most important stage of production, and therefore only professionals are employed in it. There are no random people in these positions - it's easier to get selected by Google than to get the right job at Cohiba.

8. The next stage of production logically follows from all the previous ones: tobacconists who are responsible for the shape of cigars come into play. To give the final product the correct shape, it is necessary to have a good command of the chavette - this is a special knife with which the stem is cut and the edges of each leaf are trimmed. If the cigar is based on a whole tobacco leaf, then there are no barriers to the air passing through the cigar. The smoker thus gets the opportunity to fully enjoy the finest shades of aroma.

9. The future flavor is determined by the nature of the filling - the central part of the cigar. The locals call it tripe. It is based on several whole tobacco leaves, the most fragrant and coarse, folded like an accordion. As a rule, a tripa consists of three sheets, and if the first sheet is the most fragrant, then the other two serve a completely different purpose - they provide a mild taste and good burning.

10. In order for the filling to be firmly held in place and not fall apart, it is wrapped in a capote - a strong thin sheet that is pre-pressed in a given shape.

11. The appearance of a cigar is determined by the mouthpiece - this is the part of it that is made from the most expensive tobacco leaves, impregnated with the best essential oils.

12. When sorting cigars into boxes, thickness and color must be taken into account. This knowledge is available only to a few - only the most experienced Cuban masters with big names control this stage of production.

13. Slowly but surely, we have come to the final stage of the production of elite Cuban cigars - labeling. The nimble hands of factory workers confidently maneuver between boxes full of cigars and paste the tags required by the documentation. Note that there is no question of any automation here: all tags are glued by hand, and each of them is strictly registered.

14.

15.

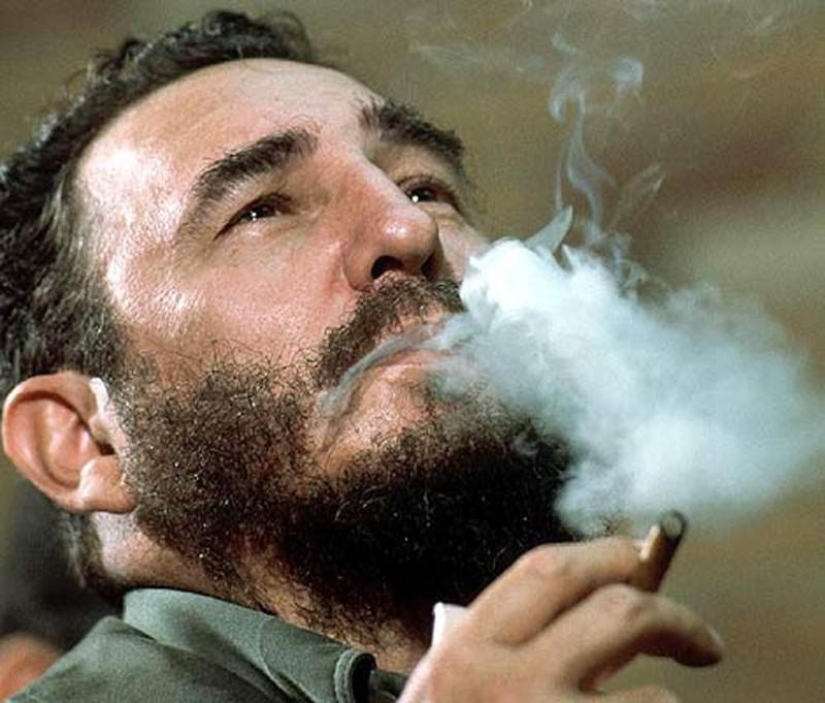

16. Cigars are stored in rooms where there are no temperature fluctuations, because when the temperature rises, there is a risk of tobacco bugs appearing. Ideally, cigars should be stored in special boxes made of noble wood - humidors. In such favorable conditions, each cigar has a good chance to celebrate even a tenth anniversary. Unless, of course, it is not smoked before.

17. In 2009, the Cohiba factory celebrated its 40th anniversary. On this occasion, the company released the most expensive cigar in the world - Cohiba Behike. Be careful: it has been noticed that when looking at this miracle, the desire to smoke it arises even among those who have never even thought about tobacco.

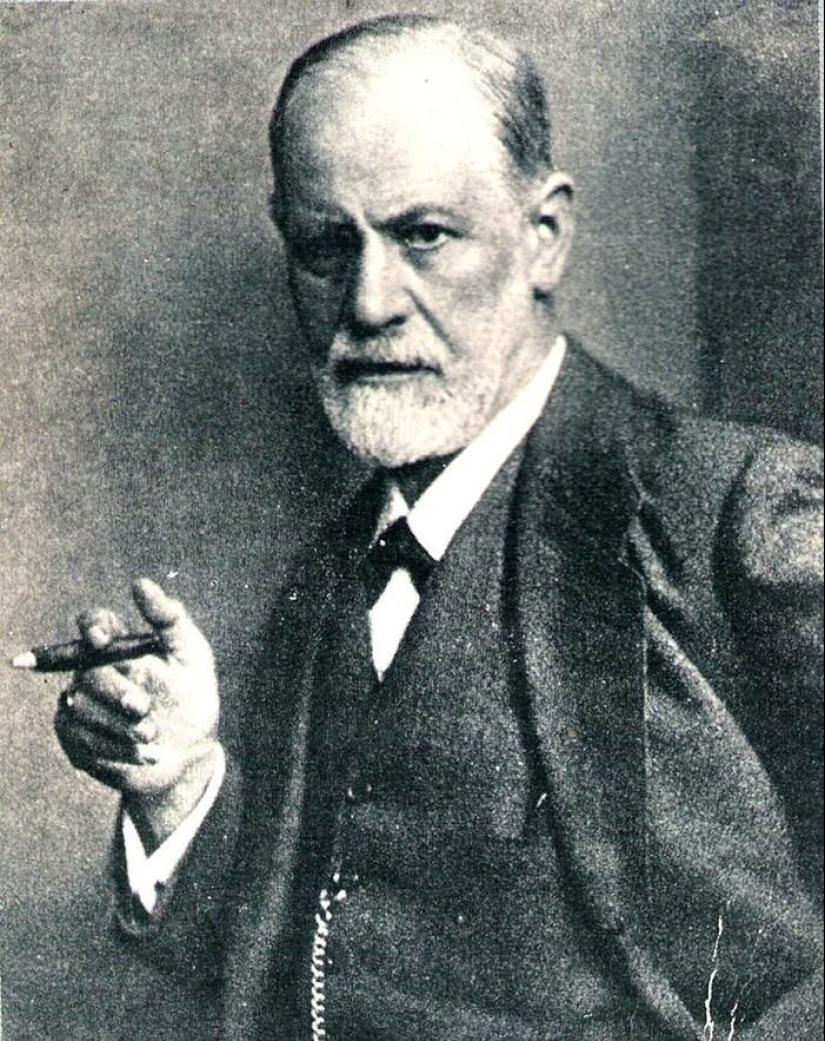

18. PS Once, Sigmund Freud, in response to the laughter of students who saw him with a cigar in his mouth during a lecture, said: "Sometimes a cigar is just a cigar." Arguing with Freud is like being offended by God, but let us note that the very process of smoking cigars has long outgrown the status of a habit and has taken shape in a completely full-fledged cultural phenomenon.

Recent articles

Jacques-Henri Lartigue (1894-1986) is perhaps the most famous "amateur" in the history of photography. The art world discovered his ...

It turns out that an active lifestyle is useful not only for the body but for the brain. Exercise strengthens muscles and spirit, ...

Related articles

Many guests of the Island of Freedom, barely having time to set foot on Cuban soil, hear from the guides & # 8212; " Have time to ...

Meyer Lansky is one of the most successful gangsters in the history of the United States. He was born into a poor Jewish family, ...

Belgian photographer Frieke Janssen created a social project "The beauty of a bad habit" ("The beauty of an ugly addiction"), in ...

Most major companies profanity is not encouraged. It is considered that the profanity — it is a sign of disrespect for ...