How Getwear jeans are sewn

Categories: Production

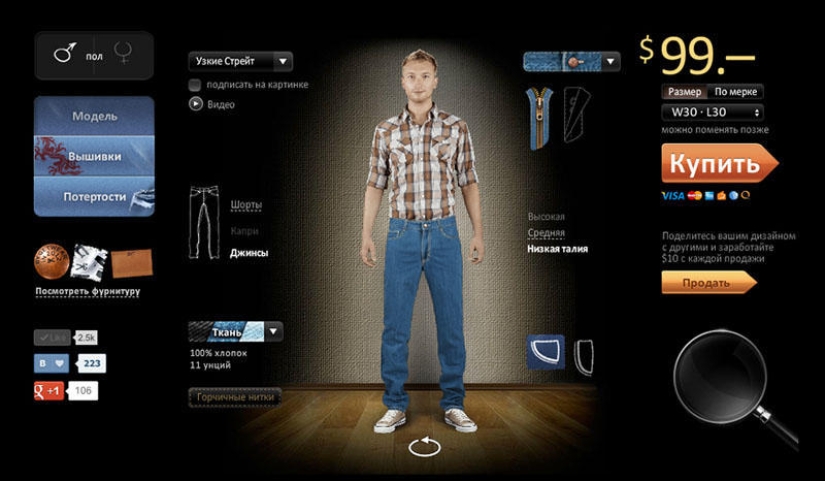

By Pictolic https://pictolic.com/article/how-getwear-jeans-are-sewn.htmlGetwear is a service where you can order a unique pair of jeans of your own design, made to measure. At the same time, jeans are much better than store-bought jeans, but they cost only a little more. Today we will talk about how Getwear jeans are made. It all starts... at your home. With the help of a special Constructor on the Getwear website, you can create jeans of your own design. The possibilities of customization are almost limitless: from choosing a style to applying a wide variety of patterns, embroideries and scuffs.

(Total 17 photos)

After you create a jeans design, it will go to Getwear production. It is located in India, in Mumbai. In India, everything starts with Nickel. Nickel Bafna is a hereditary textile worker who graduated from an Italian institute, a young and very smart Indian. He runs Getwear production. In the photo below, he is sitting in his own design jeans on various types of denim. Getwear buys the very best denim, just like Levi's buys for its top models.

Before sewing jeans, they need to be cut. The designer-cutter is engaged in cutting. He used to run his own atelier and now works for Getwear.

At Getwear, all patterns and patterns are made automatically, so the engineer only has to check them, and carefully cut out the details of the jeans with large tailor's scissors.

The cut out details of future jeans are once again checked and assembled into "knots". An image with a design and a checklist for multiple checks are attached on top.

In production, everything starts with threads - Getwear uses very strong and thick ones. One pair of Getwear jeans uses four times more thread than the average pair of mass-produced American jeans.

Getwear jeans are hand-sewn on single-needle machines. A manual approach to every detail takes more time, but allows you to win many times over in quality. One tailor sews one pair of jeans from start to finish, carefully sewing and looking at every stitch.

Getwear has something to spend on this amount of durable thread. For example, a triple closed seam in the groin is a heavy-duty groin seam that cannot be found even on expensive mass-produced jeans. You can read more about the quality of jeans on a special page.

The production employs only professional tailors with extensive experience in jeans production of world brands. They do not need to be explained how to sew a quality pair. However, self-control does not hurt - all stages of production are checked according to the checklist.

By the way, in India, men work as tailors, there are almost no women - and all because of the cultural characteristics of the country.

A new, pristine pair of jeans is customized to the customer's design. Decorative “scars”, scuffs and scratches are applied to jeans.

Now artificially aged jeans are in fashion. In order for beautiful scuffs to appear on them, jeans are put on special inflatable balloon legs and treated with bleach. The bleach is initially pink, but then fades to white.

By the way, recently Getwear sewed jeans of a very large diameter - so large that the jeans fell off the inflatable "legs" and did not allow themselves to be treated with bleach. The employees decided to pump up the “legs” a little, but they could not stand it and burst along with the jeans. Luckily no one was hurt by the denim.

Then the jeans are washed in industrial washing machines with special substances that soften the fabric and make it more pleasant to the body. However, Getwear has raw denim jeans for true fans.

Ready jeans are thoroughly dried.

All that was left was to install the hardware. Getwear uses accessories from Japanese and Swedish brands, durable and hypoallergenic. Scattered on the bottom right are Getwear Collectible Coins - you'll find one in your jeans pocket.

That's it, jeans are ready! The whole process of creating jeans from cutting to packaging takes about a week, and another five or six days are spent on delivery by courier.

This is how jeans are made at Getwear - by the hands of these handsome guys:

Recent articles

This is for us, people, the New Year is one of the most important holidays of the year. But for animals, it's all a fuss, running ...

A couple of years ago, Saudi Arabia officially banned celebrating the New Year. But this state is far from the only one where our ...

Related articles

Time not only changes the appearance and habits of the people, but also force us to drastically change some things. To them ...

We believe that someday monuments to computer repair workers will appear on the squares of our cities. A lot depends on them today ...

Without a doubt, jeans are universal clothing that unites people of different nations and continents, religions and beliefs, age ...

While the sun practically disappeared from the sky above the Arctic Circle and the night seemed endless, the Vikings prepared to ...