Through thorns to gold

Categories: Production

By Pictolic https://pictolic.com/article/through-thorns-to-gold.htmlOver the entire history of mankind, about 170 thousand tons of gold have been mined. The main part of it has settled in the underground vaults of banks in the form of ingots, some on the fingers, ears and necks, something rests in chests at the bottom of the seas, and something flies into space and is in our pockets in the form of microelectronics particles in mobile phones.

Most of these 170 thousand tons have been received over the past 150 years. Today's scale of the industry would drive a gold digger of the XIX century crazy: 3 thousand tons of gold bars are mined in the world per year, and 100 railway cars are needed to accommodate them! And a considerable part of this gold is mined here in Russia.

Deposit — enrichment — smelting. It is such a simple, at first glance, path that a grain of gold goes to get from the bowels of the earth into your wedding ring or into an ingot in a bank vault. The path is simple, but rather thorny, as you could see from the reports from the quarry and the processing plant. Gold can only be smelted — it would seem that it is easier? But it's not as easy as it seems! You remember that a stone is turned into gold, so even at the final stage you need to work hard.

We are going to the Amur Hydrometallurgical Combine of Polymetal company — gold ore concentrate is brought here from the Albazino processing plant in the Khabarovsk Territory and from Maysky in Chukotka.

The plant receives about 160 thousand tons of concentrate per year, which is transported in bigbags in winter by trucks along the winter road, and in warm weather — on barges along the Amur. To extract gold from the ore that comes to the Amur Combine, the method of autoclave oxidation is used. Compared to other methods, it has a higher degree of extraction, which is extremely important in the case of gold.

The hydrometallurgical plant begins with a raw material warehouse — just like a processing plant. But if at the factory it was mountains of stone with varying degrees of precious metal content, then here are even rows of 16-ton "bags" with a flotation concentrate — gold-containing gray balls. Each of these big bags contains about 700 grams of gold.

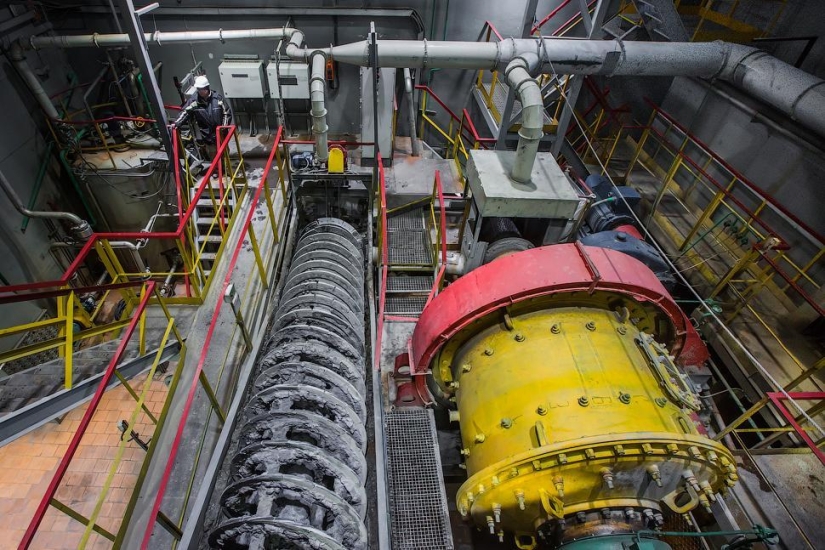

First of all, the big bags with concentrate are unloaded into a shredder, or, as they say here, they are melted. The shredder is like two drops of water similar to the mill used to grind stones at a processing plant, only much larger. Balls with a diameter of 60-100 millimeters again turn the concentrate into flour, water is added to it, and then pumps pump the pulp into a storage tank.

Interestingly, the pulp from different deposits (May and Albazinsky) enters different storage units, because they have different sulfur content. For the best result of the oxidation reaction, the specific sulfur content is important, and this is achieved using a cocktail of these two accumulators. The cocktail is prepared in a special container with a volume of 500 cubic meters. Of course, it is not the bartender with a shaker who is responsible for this, but the automation system.

When the mixture is ready, it is sent to the autoclave — the main unit at the plant. This huge device for the plant was made by special order in Asia and delivered first by sea to Vladivostok, and then on special railway platforms to the construction site of the plant in 2011. It was a whole special operation: the weight of the autoclave was 163 tons, and the length was 25 meters. Only when the autoclave was installed, the installation of the rest of the equipment and the construction of the buildings began. So we can say that the whole enterprise was built around this autoclave.

Since the flotation concentrate is obtained from resistant ores, the gold particles in it are enclosed in a microscopic shell, and it must be destroyed to extract gold. This is what happens in the autoclave by oxidation. That is why — in order to ensure a chemical reaction — there must be a certain amount of sulfur in the pulp. The reaction occurs at about 200 degrees under a pressure of 21 atmospheres.

Inside, the autoclave is divided into five sections of different volumes, equipped with agitators, through which oxygen is supplied inside for each agitator. Oxygen is produced at a special oxygen station here at the plant. During the operation of the autoclave, sulfur oxidation is achieved up to 98%. Then the oxidized pulp is cooled to 40 degrees and sent for neutralization.

During neutralization, a suspension of limestone and lime is used. Next, the pulp is sent for sorption leaching in special containers, in which activated carbon and sodium cyanide are used. Cyanide is served first. It converts ordinary particles into charged ions. Then these ions are deposited on activated carbon, which moves towards gold. Sorption tanks are installed in a cascade so that the beginning of sorption is higher than its final stage. The pulp flows from the containers to the end of the process. As a result, coal is obtained, on which all the gold from the pulp is collected. Now it's liquid gold. Magic!

All these processes take place continuously and under automatic control from the control center.

But no one needs liquid gold, so it is necessary to convert it into a solid form. This is done by electrolysis. The desorbing solution of gold is sent to the electrolyzer. In it, an operating current is supplied to the cathodes and anodes. During the electrolysis process, gold is deposited on the cathode. Well, then the cathode precipitate is sent to the final stage — to a strictly guarded gold smelting room. Here, the cathode precipitate is dried in furnaces and it is mixed with soda, borax and saltpeter to remove the remaining impurities from the metal.

The resulting gray powder is sent to a melting furnace.

The melting point of gold is 1064 degrees. When the gold, as they say, has boiled, it is boiled for about an hour. That's what they say: "It is necessary for the metal to boil." The spill begins at a temperature of about 1200 degrees, and few people can see it — so strict security measures at the gold smelting site.

The gold content in these bars is different, and it is not 99.99%, as many people think. At the beginning of the spill, the metal is lighter, there is less sample in it, by the end the sample is higher. After the ingots cool down and the slag is removed from them, a sample is taken from each.

This is not at all the gold that is stored in banks — this is the so-called dore alloy, and the gold content in it is about 70%. Bank ingots and gold of the highest, 999.9 samples are produced from dore ingots at refining plants. In other conditions, it is impossible to get gold from dore bars.

Therefore, when ingots fell out of the plane of a Canadian company in Yakutia, the hunters for easy prey did not have much sense to look for them. These ingots simply cannot be artistically processed by themselves, nor sold to jewelers: they do not even need them for free.

That's how a grain of gold has to go through a thorny path — from boulders at the bottom of the quarry to gold bars. Behind it is the work of a huge number of people and dozens of technological operations.

Keywords: Far East | Gold | Gold mining | Combine | Metal | Partner post

Post News ArticleRecent articles

It's high time to admit that this whole hipster idea has gone too far. The concept has become so popular that even restaurants have ...

There is a perception that people only use 10% of their brain potential. But the heroes of our review, apparently, found a way to ...

Related articles

Human intervention in the affairs of nature is extremely rarely successful. Especially a lot of trouble was brought to the ...

Residents of the Peruvian city of La Rinconada, located in the Andes near the border with Bolivia, live at the altitude of 5100 ...

Islam — it is the religion of enjoining the believers to adhere strictly to certain rules and rituals. Most of them are ...

New Year's is a time to surprise and delight loved ones not only with gifts but also with a unique presentation of the holiday ...