People have been mining gold for more than 6 thousand years, and gold mining can be called one of the oldest industries. It just so happens that the yellow metal has a special value for humanity. Therefore, there have always been adventurers who are ready to go in search of gold even far away, and the best minds were constantly thinking how to get a precious metal from some substance that costs nothing. Medieval alchemists tried to do everything in their attempts to get gold from lead or copper, and for many hundreds of years they failed.

Oh, if alchemists got into our time, they would definitely go crazy if they found out that almost all the gold in the world is obtained... from stone.

No, after a minute, of course, they would have calmed down a little: they would have been told that gold can not be obtained from any stone. It should be a gold-bearing ore, which must first be explored, and then extracted from the bowels of the earth. This is not as simple a process as it may seem at first glance. And deposits of gold-bearing ores, as a rule, are located in the most inaccessible and previously little-developed places of our planet.

We talked about mining the coveted gold-bearing stone earlier. In the new story, there is a story about the wonderful work of modern alchemists who take out the cherished 5-7 grams of gold from a ton of gray stone.

In the story about the extraction of gold ore from a quarry, we stopped at where 100-ton dump trucks bring the extracted piles of "precious" gray stone. These gold-bearing ores are called persistent: it is impossible to extract gold from them in a simple way, by leaching. In addition, the gold content in this ore is such that it is economically feasible to extract it on the spot, and not to transport it for many hundreds of kilometers to the "alchemist factory".

To do this, a processing plant was built right at the Albazino deposit in the Khabarovsk Territory (Albazino belongs to one of the leaders of Russian precious metals production — Polymetal). It is here that the first stage of the transformation of stone into gold takes place — the enrichment of ore. 1.6 million tons of ore are processed at the deposit per year!

All the extracted ore is brought from the quarry to the factory and unloaded at the warehouse, which is called the ore yard. It is important to understand that not all mined ore is the same. Gold is not coal, which lies in huge layers. Gold-bearing horizons lie in different parts of the deposit, have different volumes and different contents of the yellow metal in the ore: somewhere 1-2 grams per ton, and somewhere more than 10. Ores with different gold content are unloaded into different sections, called stacks. Then, when the ore is loaded for processing, different amounts of stone are fed from different stacks, so that on average the same calculated gold content per ton of ore is obtained. For the Albazino deposit, this is 5-7 grams per ton.

The ore is fed to the receiver using a special loader. A 70×70 cm restrictive grating is installed at the receiver entrance so that too large boulders do not fall on the conveyor belt, which can damage the mechanism and get stuck on the conveyor. Large stones are broken with a pneumatic butoboy.

First of all, the ore needs to be crushed: thousands of tons of stone turn nothing less into dust. That huge stone that you saw in the photo above is broken into trillions of pieces measuring 71 microns! How is it possible to do this?

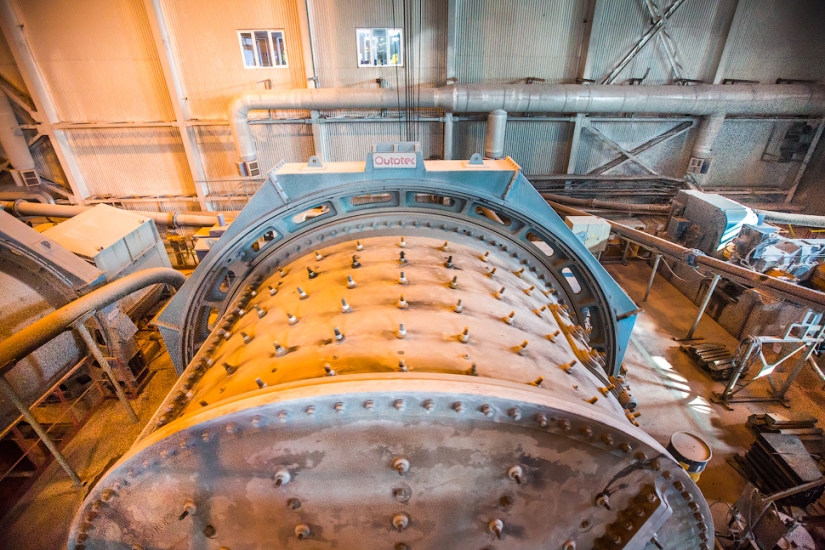

Several giant mills come to the rescue. First, the ore enters the self-grinding mill through the conveyor. This is a huge rotating drum, somewhat resembling the drum of a washing machine, only a little bigger: its volume is 64 cubic meters. Being in constant motion, the stones fall on each other and turn into rubble. Now comes the turn of ball mills. Inside them are metal balls that grind crushed stone into flour quite quickly.

Water is supplied to the mill with gold ore flour. The resulting mixture, pulp, is fed under pressure into two hydrocyclones. These aggregates, due to the centrifugal force that occurs during rotation, classify the pulp: large particles are sent for grinding, and everything else is sent to the main stage — flotation. Flotation is the enrichment of ore.

Flotation in Albazino takes place in 28 flotation machines, each with a volume of 50 cubic meters. In the flotation machine, the pulp is constantly mixed and saturated with air. It is supplied with special reagents — collectors, activators and foaming agents. Activators at the molecular level prepare the surface of the mineral for the action of the collector reagent. The collector makes the surface of gold hydrophobic, so that its particles attach to air bubbles and rise to the surface of the flotation machine, separating from unnecessary rock. The foaming agent collects air bubbles with gold particles into foam on the surface of the container.

This dark foam is actually golden. It is collected from the surface of flotation machines and sent to a thickener. Here, the foam is converted into so—called floccules - gold ore concentrate with the help of flocculant and coagulant. Getting into the thickener, the foam contains about 10% of solid particles, and at the exit they are about 50%. From here, the mass is pumped to the press filters, where it is squeezed out of excess water.

The resulting product called "cake" is dehydrated, but still too wet and not ready for transportation, so it is sent to the oven. The furnace is a huge 16-meter pipe with chains inside. Here, at a temperature of about 500 degrees, the cake is dried and crushed at the same time due to the rotation of the pipe and chains.

And finally, the finished product of the processing plant comes out of the furnace — dried concentrate. The gold content here is about 50 grams per ton, that is already 7-10 times more than the original. Thus, during the enrichment, it was possible to reduce the volume of gold-containing material and bring it into a more convenient form for further transportation and processing.

The gold ore concentrate is packed in special soft containers (big bags) weighing about 16 tons each and sent to the third, final stage — to the hydrometallurgical combine, where the substance will be turned into gold bars. But we will talk about this in the next article.

Keywords: Far East | Gold | Gold mining | Metal | Partner post | Ore | Factory

Recent articles

It's high time to admit that this whole hipster idea has gone too far. The concept has become so popular that even restaurants have ...

There is a perception that people only use 10% of their brain potential. But the heroes of our review, apparently, found a way to ...

Related articles

Human intervention in the affairs of nature is extremely rarely successful. Especially a lot of trouble was brought to the ...

Residents of the Peruvian city of La Rinconada, located in the Andes near the border with Bolivia, live at the altitude of 5100 ...

Islam — it is the religion of enjoining the believers to adhere strictly to certain rules and rituals. Most of them are ...

New Year's is a time to surprise and delight loved ones not only with gifts but also with a unique presentation of the holiday ...