How the Superjet is made: Komsomolsk-on-Amur

Categories: Production

By Pictolic https://pictolic.com/article/how-the-superjet-is-made-komsomolsk-on-amur.htmlAlexander Cheban says: “An airplane is not a car, it is a very complex, one might say, “piece” product, assembled by hand. It is here that the fact of numerous doubts and distrust of an ordinary air passenger is hidden.

I think that my readers have already flown a Superjet, but many of them will fly one of the six Superjets of UTair this year. Today I invite you to take a look at the production of this beautiful aircraft. I showed the Airbus factories in Hamburg and Toulouse, the Boeing factories in Everett and Renton, of course, I was very interested to see how the aircraft is assembled in Russia. The most complicated process, where no one has the right to make a mistake, where there is multiple control at each stage of the assembly. In 2013, 25 aircraft were assembled, and this year 40 Superjets will be assembled! Currently, the production cycle is 10 days, with plans to reduce it to seven!”

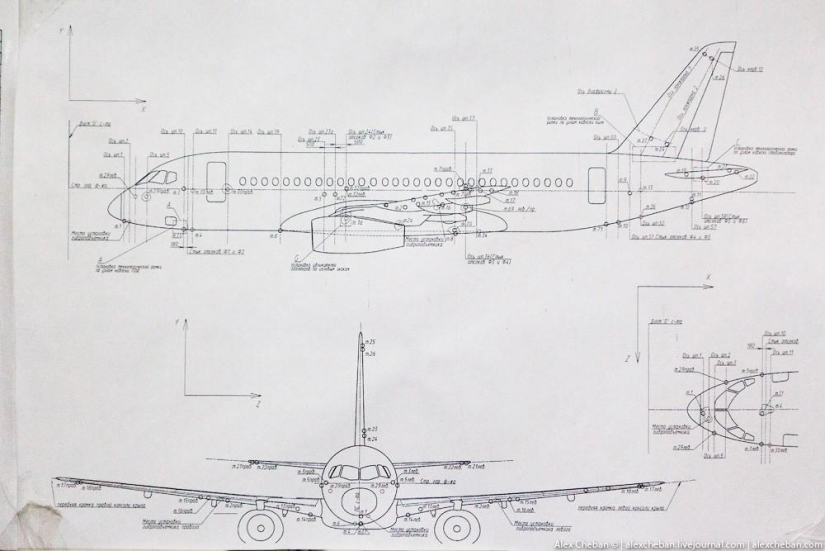

1. I'll start the story about the production of the Superjet with a photo report from the plant in Komsomolsk-on-Amur. Although, of course, everything starts much earlier ...

The production of the aircraft - its final assembly - is carried out by the Komsomolsk-on-Amur branch of CJSC Sukhoi Civil Aircraft (KnAF) with the direct participation of other plants in Russia, where components of the Sukhoi Superjet 100 are manufactured. Finished parts are transferred to the Komsomolsk-on-Amur branch Sukhoi Civil Aircraft CJSC, where the final assembly of the aircraft is carried out.

Parts are manufactured and modular assembly of compartments is carried out in Novosibirsk, parts made of polymer materials are produced in Voronezh. But the first of the main locations where you can see the aircraft from the assembled fuselage to the flying side is Komsomolsk-on-Amur.

As with the Boeing or Airbus, the assembly is carried out according to certain production areas.

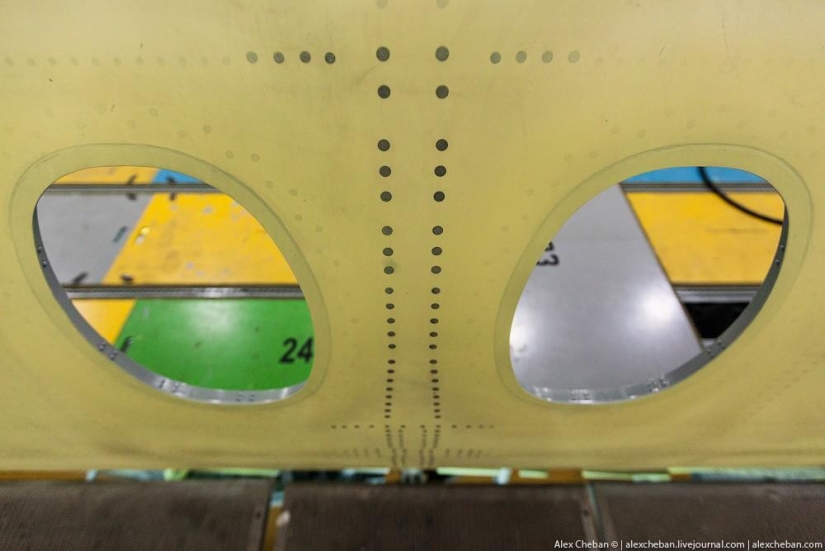

2. This is how the fuselage assembly shop looks like.

3.

4. Here, the fuselage compartments are docked, racks for radio and electrical equipment are installed.

5.

6. Also installation of the floor, luggage compartments, doors. It is very interesting to see the "evolution" of the aircraft, moving from station to station.

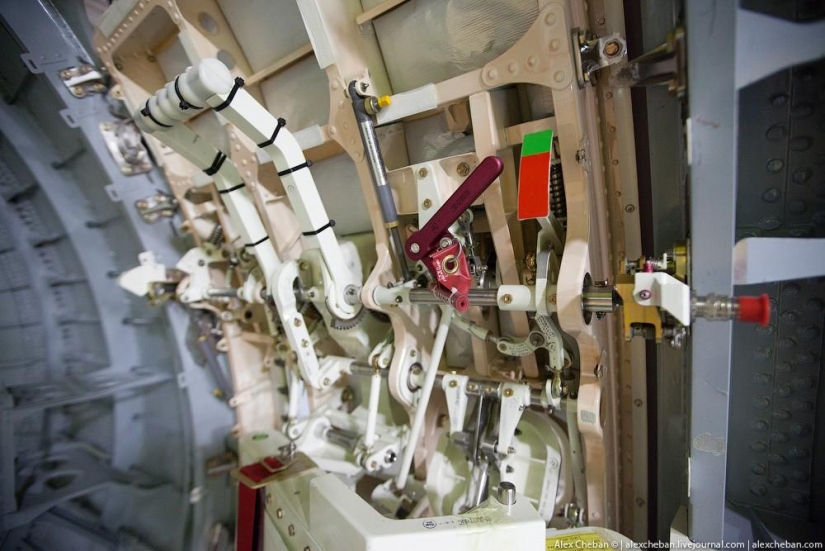

7. Pay attention to how many elements a regular passenger door has! Although, of course, she is not ordinary at all.

8.

9.

10.

eleven.

12.

In the fuselage assembly shop, heat-insulating preparation is carried out, as well as installation of brackets for electrical equipment. Here, in this example, the "birth" of the aircraft cabin is very clearly visible.

13. Clean interior and floor installation.

14. Thermal insulation preparation.

15. Here I'm getting ahead of myself a little, the electrical equipment is already in place. This shot was taken in the final assembly shop.

16.

17.

18.

19.

20. Next, we move to the neighboring workshop, which is the final assembly workshop. Here the aircraft moves through seven sections, from where it is transferred to the flight test station.

21.

22.

23.

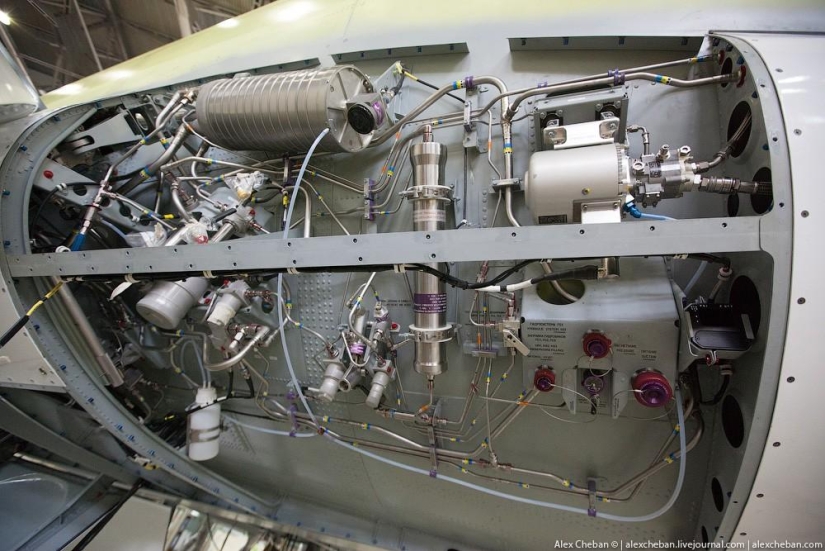

24. Installation of the auxiliary power unit and nose cone.

25. Installation of the front and main landing gear.

26.

27.

28. The painting of the finished aircraft in the livery of the airline is carried out in Ulyanovsk or Venice, although some small elements are painted right here.

29.

thirty.

31. Hydraulic elements… difficult?! Only electrical cables look more complicated! Absolutely all assembly processes undergo multiple quality control. Each worker is responsible only for his own area and a certain list of works.

32.

33. At the end of 2013, a new multimedia training system was introduced here, all this works in a neighboring building, training and control takes place on the job.

All innovations and even very minor nuances make it possible to reduce assembly time in one area, just as it happens on Boeing and Airbus. The Superjet is still a very young project, so every achievement in the production process is a small feat.

34. Aircraft assembly is not a conveyor belt, it is people. At each stage, our group was accompanied by engineers and heads of workshops, you should have seen their enthusiasm and energy! And what girls work here!

35. Installation of elements of the luggage compartment in the process ...

36. ... and after its completion.

37. In the last sections, the operation of the landing gear is checked, the aircraft is prepared for delivery under current, and equipment blocks are installed.

38.

39. And here is what an emergency registrar looks like, or a “black box” in the language of the layman. And he's not black at all.

40.

41.

42. In a separate report, I will show the cockpit of the Superjet at different assembly stations and in the final version.

43. The plane is assembled! At this point, it is transferred to the flight test stage. As a rule, the flight program of each new aircraft consists of eight flights during which systems are tested in the air.

44.

45. It's a little strange to see "Remove before flight" in Russian.

46. Well, where is the reportage without serious guys?!

Keywords: Aircraft

Post News ArticleRecent articles

It's high time to admit that this whole hipster idea has gone too far. The concept has become so popular that even restaurants have ...

There is a perception that people only use 10% of their brain potential. But the heroes of our review, apparently, found a way to ...

Related articles

The invention of flying machines that allow people to travel into the Earth's atmosphere is a list of the greatest innovations of ...

All the boys, and perhaps some of the girls, loved to climb on different equipment as a child. Well, to get into the cockpit of an ...

In front of these people appear the most spectacular and ever-changing landscapes — from stunning atmospheric phenomena to the ...

New Year's is a time to surprise and delight loved ones not only with gifts but also with a unique presentation of the holiday ...