How Lifan cars are assembled at the Derways factory

Categories: Auto | Production

By Pictolic https://pictolic.com/article/how-lifan-cars-are-assembled-at-the-derways-factory.htmlTimur Agirov aka timag82 writes: “Another enterprise that I specifically visited in Cherkessk is the first private automobile plant in Russia, Derways, which successfully assembles Chinese brand cars. I offer a photo report that captures the main moments of the assembly - from unloading containers with CKD kits to loading finished cars into car carriers.

A few words about Derways. The name Derveys is made up of the names of the founders, these are the Derevy brothers, widely known in the republic, and the English word “roads”. At first, in 2002, it was a small automotive division of the Mercury holding, which two years later released an SUV of its own design, the Cowboy. In 2005, the Romanian company APO, a chassis supplier, went bankrupt, and the owners refocused production on the assembly of Chinese cars. Car kits were produced in China, imported to Russia, assembled and sold here. Now these are the brands Lifan, Khaima, Geely, as well as Great Wall Hover. The production capacity of the plant is 130,000 cars a year, the company employs at least 1,000 people, which is essential for Cherkessk. So let's see what it looks like."

(Total 42 photos)

Source: Journal/timag82

1. At the checkpoint. To the right is the administration building. Behind it is a large territory of the plant, 23.5 hectares.

2. Let's go directly to the customs zone and the zone where the containers with the complete set are stored, arriving here by sea from China, Chongqing, where the headquarters of Lifan Industrial Group is located.

3. Vehicle kits are unloaded, something is delivered to the warehouse, something immediately leaves for the welding shop.

4. Let's go to the welding shop.

5. The welding shop consists of three sections - a sub-assembly, the main welding line and a section for hanging and straightening, from where the body is sent for painting (the line is at the end of the hall in the photo).

6. Welding is partly automated, partly manual labor is used.

7.

8.

9. Before we get to the next painting shop, we go through the lock, we are given special clothes.

10. In the photo - Rustam Lakhov zahho, with whom we went on excursions, it was thanks to his support that I got to the plant, for which I thank him very much!

11. Paint mixing room. Because production is dangerous, it can only be seen through glass.

12. The line for preparing bodies for painting consists of 14 baths, in which each body is first cleaned by immersion in a special solution, then primary primer is applied to it by electroplating, after which the body is washed again.

13.

14. Then the bodies enter the line, where the seams are processed and dried at high temperature.

15.

16. Cleaning the body before painting.

17. 8 Japanese-made painting robots apply enamel. The painting operation takes literally 5 minutes, and 10 seconds are enough to change the paint.

18. The whole process is automated and controlled from outside the spray booth.

19. The paint shop consists of three floors, painting is carried out on the second, in order to lower the car to the first, a special elevator is provided.

20.

21.

22. After painting, the body enters the drying chamber, where it stays for 45 minutes at a temperature of approximately 160 degrees.

23. Then the bodies move to the assembly shop.

24.

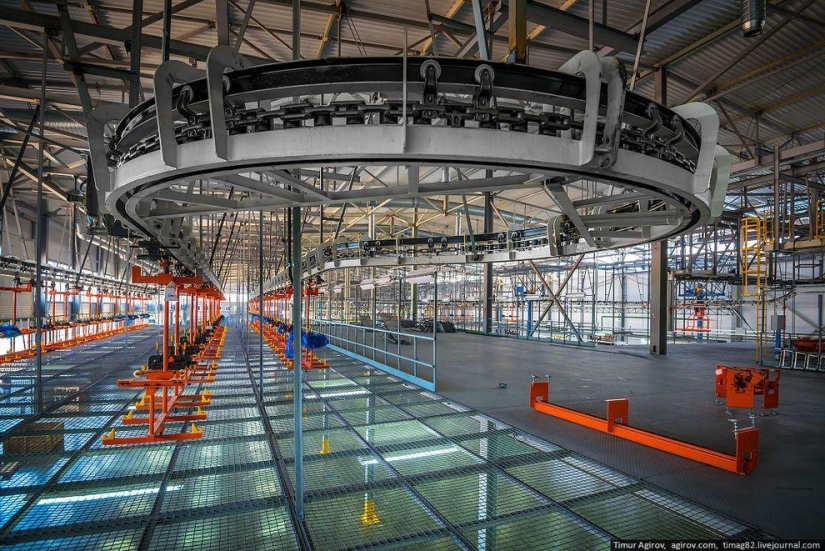

25. Before going to the assembly shop, we went into the neighboring rooms, in which another assembly line is being installed.

26. This is how a brand new assembly shop looks like before the installation of equipment in it

27.

28. I took these photos in the summer, at the present time, I think, the equipment has already been installed - from January 2014, Derweiss begins to produce new models, perhaps this will be done here.

29. And this is a general view of the current assembly shop.

30. There are two lines, they can produce up to 80 thousand cars a year.

31. Chassis assembly area.

32.

33.

34.

35. Finishing assembly area.

36.

37. The finished car leaves the assembly line. On the line, by the way, cars of different brands are assembled at the same time.

38. German-made diagnostic section.

39. Washing.

40. After that, the car is driven to the warehouse of finished products.

41. The warehouse makes up a large part of the plant area.

42. Cars are shipped to dealers through their own company Yug-Trans, which has at least 150 car carriers.

Already after I shot a photo report, information came from the news feeds that the plant began assembling cars of the Taiwanese brand Luxgen.

As usual, I do not comment on the manufactured products, but I will say a few words about my personal impressions - the plant is large (we spent an hour and a half there and did not see everything), clean, modern, it was interesting to photograph, and I am glad that such production exists in the Caucasus. Good luck, good quality products and new customers!

Recent articles

It's high time to admit that this whole hipster idea has gone too far. The concept has become so popular that even restaurants have ...

There is a perception that people only use 10% of their brain potential. But the heroes of our review, apparently, found a way to ...

Related articles

Winter — it is a difficult time for motorists, especially if the vehicle has to be left under the open sky. But besides the ...

Financial literacy is no less important than usual, because it gives us the opportunity to manage money rationally and not feel ...

Marvin Himeyer — a simple American hard worker, faced with the arbitrariness of a large corporation and city authorities. When it ...

New Year's is a time to surprise and delight loved ones not only with gifts but also with a unique presentation of the holiday ...