How famous Leica cameras are assembled

Categories: Production

By Pictolic https://pictolic.com/article/how-famous-leica-cameras-are-assembled.htmlLeica - cameras manufactured by the German company of the same name Leica Camera AG. We offer you a detailed photo story about how the legendary cameras are assembled.

(Total 23 photos)

1) Leica M8 at an early stage of assembly. Lots of mechanical parts are there, but the viewfinder, lens, and electronics are missing.

2) The Leica factory is located in the small town of Solms, in western Germany. Many employees have been with the company for over 20 years. Stefan Daniels, who currently heads the Solms plant, is one of them. He met Leica at the age of 15 and got his engineering degree through his work at the company.

3) The technician inserts the CCD. The CCD for Leica is manufactured by Kodak. The surface of the sensor is covered with many microlenses aimed at changing the incoming light rays so that they hit the sensor evenly, one microlens opposite each pixel. After the CCD is inserted, the worker assembles the lightweight magnesium body of the camera. The body hides top and bottom brass plates to protect the internal components.

4) The software is installed and the camera can operate at a basic level, allowing technicians to conduct thorough testing, on a camera-by-camera basis. By the time testing is complete, the Leica M8 will consist of 1,800 individual parts.

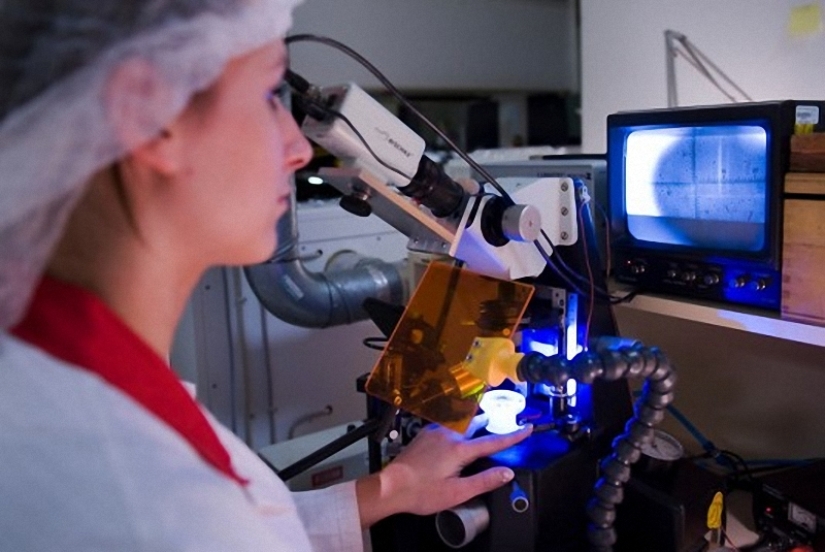

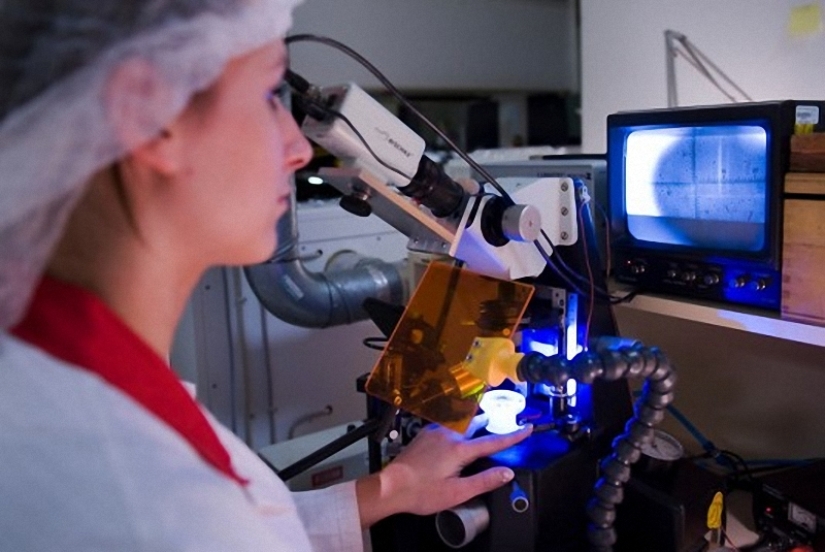

5) The worker subjects each camera to a standard system of checks: shutter speed, rangefinder, focusing system, as well as the sensitivity and coherence of the CCD. In this quality control step, the technician determines the accuracy of the camera's viewfinder. Each viewfinder must be corrected after installation, and Leica requires that the center image seen through the viewfinder differ from the real image by no more than 0.0001 millimeters.

6) The workplace is configured for the assembly of Leica analog cameras. But since the M8 and M9 have an almost identical composition of parts, they are assembled in parallel with analog cameras. The whole process involves 35 people and takes about eight hours per camera. Tiny dust particles inside the camera can cause serious problems, which is why the Leica factory has created rules for accessing the workplace. Employees wear low-static shoes to avoid attracting dust. Dust-absorbing flooring is located at the entrances to the assembly hall. All paper products on the conveyor are covered in plastic bags to ensure that even the smallest fibers that might escape from the pages cannot enter the room. And employees are forced to wear special hats.

7) M7 enclosures, ready to assemble at any time.

8) According to Christian Erhardt, Associate Director of Marketing, “The only reason our cameras are so carefully crafted is because virtually everyone in the company is a user of our products. It's in our blood." On request, the Leica M7 can be covered with ostrich skin. The “a la carte” model allows the consumer to choose the cosmetic details of the camera, such as the color of the trim, buttons and leather case. Customers can also customize the size of the viewfinder and the position of its lines.

9) The technician makes minor adjustments to the camera's rangefinder to ensure it works in sync with the lens. Much of the Leica camera setup is done with the human eye, not with computers or sophisticated optical instruments. Here, the technician checks and adjusts the manual focus mechanism using the frame-stripe principle. There are no autofocus cameras in the M-series. Leica is very proud of this line of cameras.

10) The photo shows an internal view of the Leica S2 camera. This widescreen camera has a 37.5 megapixel CCD(30x45mm) 56 percent larger than 24x36mm at 35mm frame. Its price is $22,000.

11) Ralph Hagenauer, head of Leica's product distribution department, reviews a range of cameras in the lobby of the central office.

12) They may look like giant cough drops, but these raw glass washers are meant to be ground and polished into elements for a Leica 21mm f/1.4 lens. The company buys glass from major glass manufacturers around the world, depending on optical clarity, availability and price.

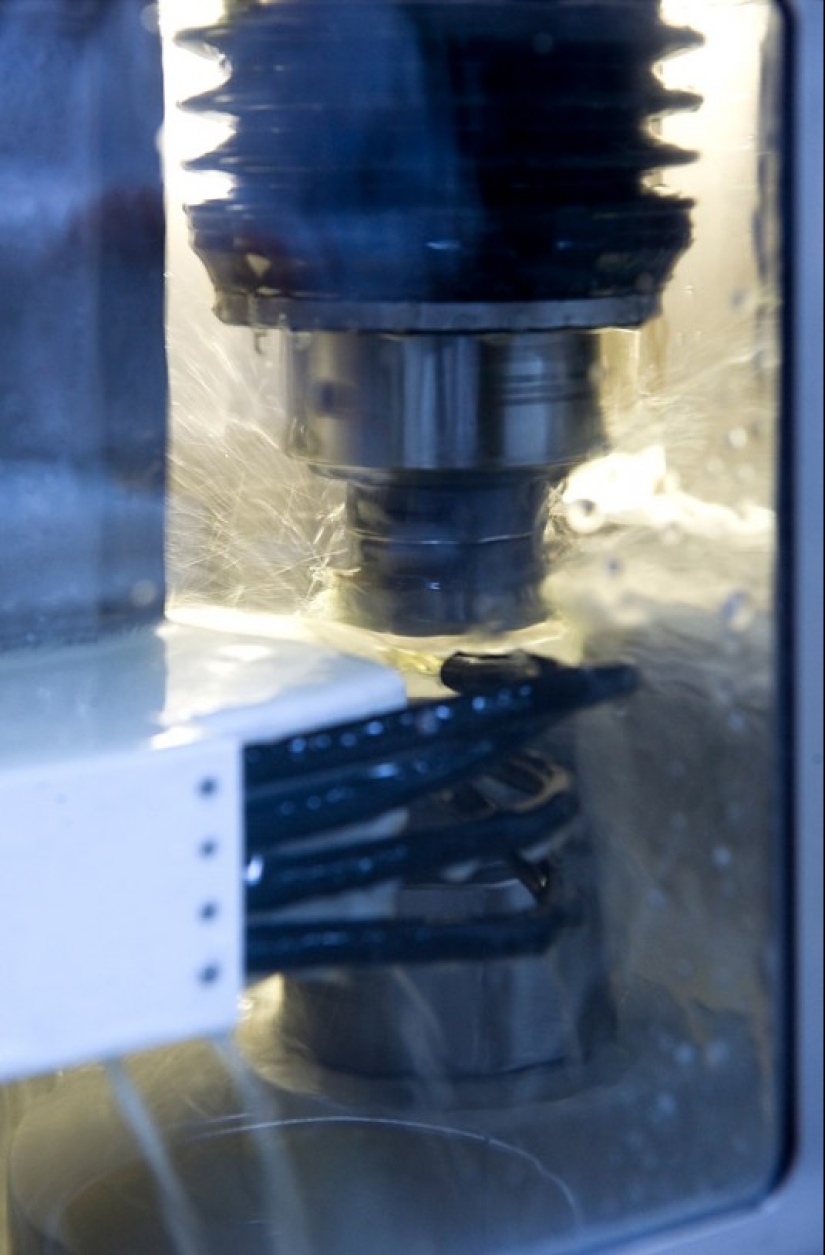

13) Much of the production equipment at the Solms factory is made to order, to Leica specifications, and often uses proprietary processes that the company keeps secret.

14) Glass washer during grinding, which will eventually become part of the Leica 21mm f / 1.4 lens

15) A worker oversees lens polishing during the lens manufacturing process.

16) Leica lenses are polished to a tolerance of about 1/2,000 mm, about a thousand times thinner than a human hair.

17) Glasses that have undergone preliminary grinding and polishing. Next, the inspector will determine which of them are suitable for further processing.

18) The computer displays a graphical representation of the passage of light through the lens. It checks light transmission from all angles and determines if the lens surface needs additional polishing.

19) Each lens has up to 43 coatings, depending on the lens model. The glass is placed in an oven where the coating material is sprayed on, then the layers are fused to the glass using a proprietary process. Each layer is designed to improve image quality and corrects for color, distortion, and other inaccuracies.

20) “Every lens, every piece of glass, is unique, we just have to make sure the end result is always high quality,” Ehrhardt says.

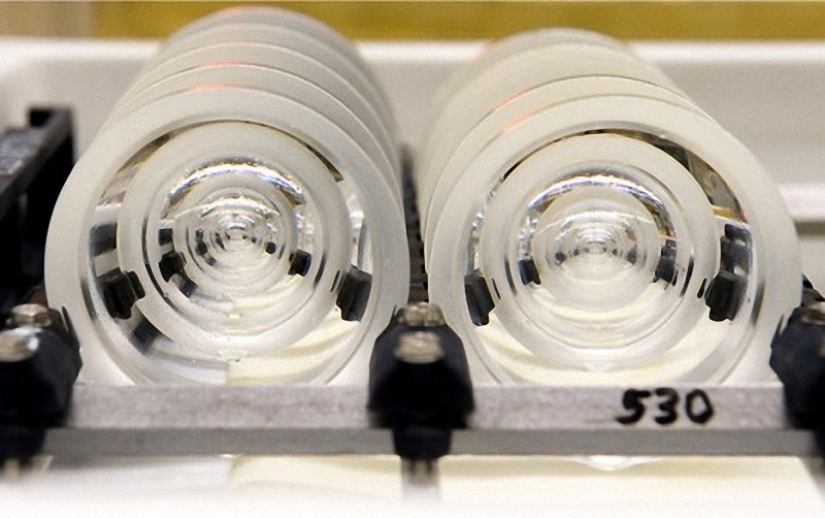

21) Finished lenses designed for the Leica Noctilux-M 50mm f/0.95 ASPH lens. The company claims it is the world's fastest aspherical lens. Priced at $11,000 per lens, this tray costs over $100,000

22) In one of the final stages of quality control, the technician projects an image of a homogeneous sample through a lens onto the wall. He then makes a visual inspection to make sure the image is sharp enough.

23) Tray of finished lenses Summilux Leica M-21mm F/1.4.

Keywords: Leica | Plant | Camera | Glass | Photo camera

Post News ArticleRecent articles

It's high time to admit that this whole hipster idea has gone too far. The concept has become so popular that even restaurants have ...

There is a perception that people only use 10% of their brain potential. But the heroes of our review, apparently, found a way to ...

Related articles

The story of a young American woman Marie Adler is one of the most high-profile cases of sexual violence. The girl who became a ...

Welcome to the wonderful and diverse world of succulents! These ornamental plants come in many different forms — sometimes ...

All of us have seen suspicious photos, which, according to those who made them, depict ghosts. But most often these pictures seem ...

New Year's is a time to surprise and delight loved ones not only with gifts but also with a unique presentation of the holiday ...